Soil Mixing Wall (SMW) is used to mix cement slurry with soil in situ to create a cohesive soil block. Strength of mixed soil is variable and tailored according to project requirements and site conditions.

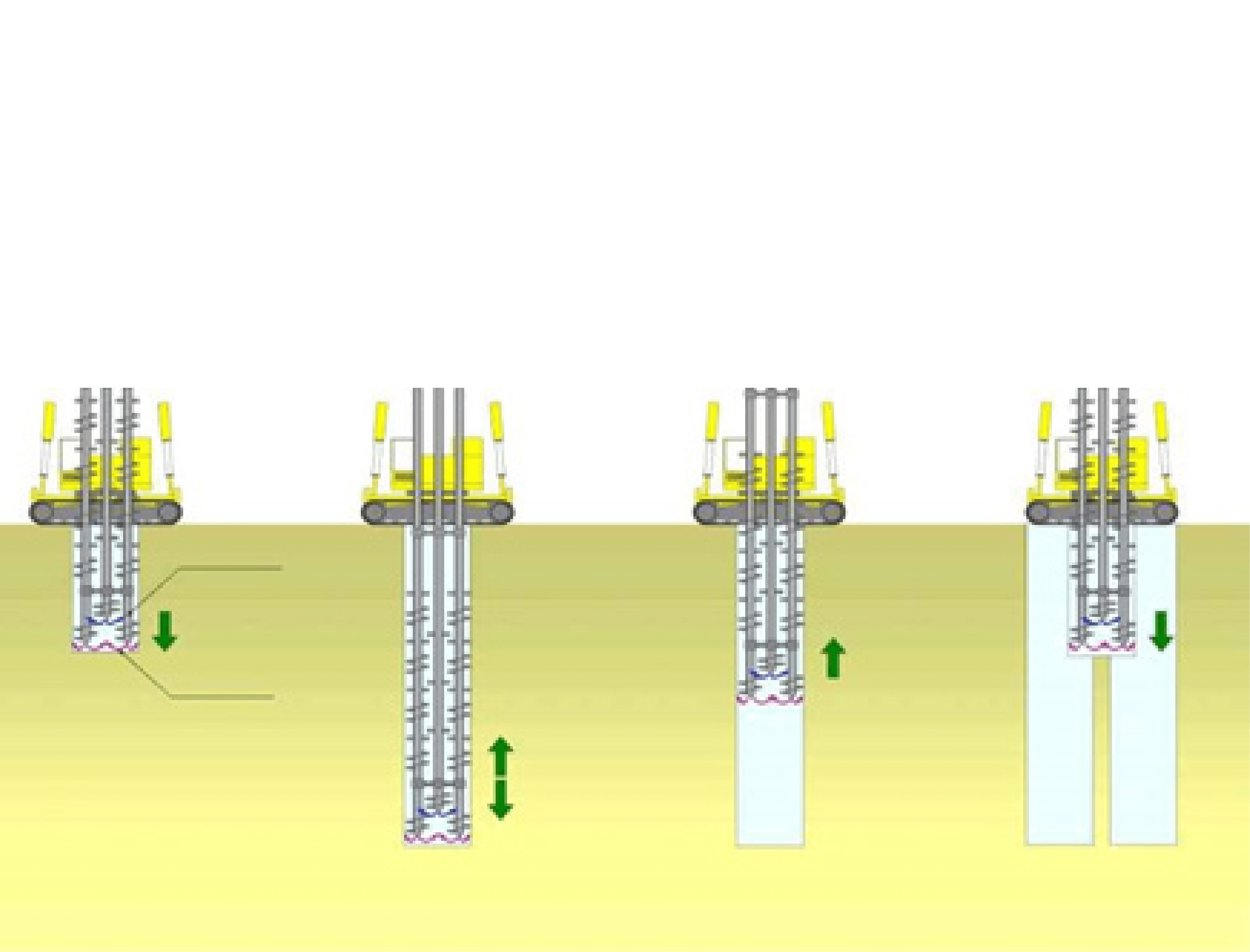

Mechanical soil mixing is performed using single or multiple shafts of augers and mixing paddles. The auger is slowly rotated into the ground. Cement slurry is pumped through the hollow stem of the shaft(s) feeding out at the tip of the auger as the auger advances. Mixing paddles are arrayed along the shaft above the auger to provide mixing and blending of the slurry and soil. Slurry lubricates the tool and assists in the breaking up of the soil into smaller pieces. A continuous soil mix wall is constructed by overlapping adjacent soil mix elements. Soil mix sections are constructed in an alternating sequence; primary elements are formed first and secondary elements following, once the first have gained sufficient strength.

ADVANTAGES

- Creates soil cement walls continuously underground, very effective at providing stiff and waterproof retaining systems to build a dry area for other construction works.

- The in-situ soil used as construction material.

- No vibrations induced during construction. SMW can be used in buildings’ immediate vicinity.

APPLICATION

- Retaining wall

To be applicable in many project such as high rise building, high way, metro station. - Cut-off-wall

The installation of an SMW cut of wall allows open cut excavation without dewatering. - Vibration Cut-off-wall

The installation of an SMW vibration blocking wall to demonstrate a stable effect.

Our Happy Clients

A Right Media Mix Can Make The Difference

Our Happy Clients

A Right Media Mix Can Make The Difference

Our Happy Clients

A Right Media Mix Can Make The Difference

No responses yet